Braking System HIL Testing Solution

2025-05-12 16:42

Technical Advantages

● Micro-high-precision real-time simulation capability

- Accurately reproduce the dynamic response characteristics of the braking system under extreme conditions such as low-adhesion roads and emergency braking

- Ensure ultra-real-time data interaction between ECU and virtual environment, with simulation accuracy of microseconds

● Customized component-level model support

- Supports import of multiple formats such as FMU and C code, and is compatible with mainstream development environments

- Customizable models of key components such as brakes, calipers, hydraulic valves, etc., to achieve full-scale adaptation from mechanical structure to control logic

- Provides verification solutions for new generation braking systems such as EMB wire control brakes and EHB electronic hydraulic brakes

● Full-process closed-loop testing

- One-stop solution from simulation scene construction, test automation, data collection to result analysis (data post-processing module)

- Improved automated testing efficiency

● Multi-intelligent fault diagnosis

- Built-in fault simulation library (such as sensor signal drift, CAN communication interruption, actuator jamming), which can dynamically trigger typical faults of the braking system, and verify the compliance of ECU fault code generation, redundancy mechanism and failure strategy in combination with diagnostic protocols to meet functional safety requirements.

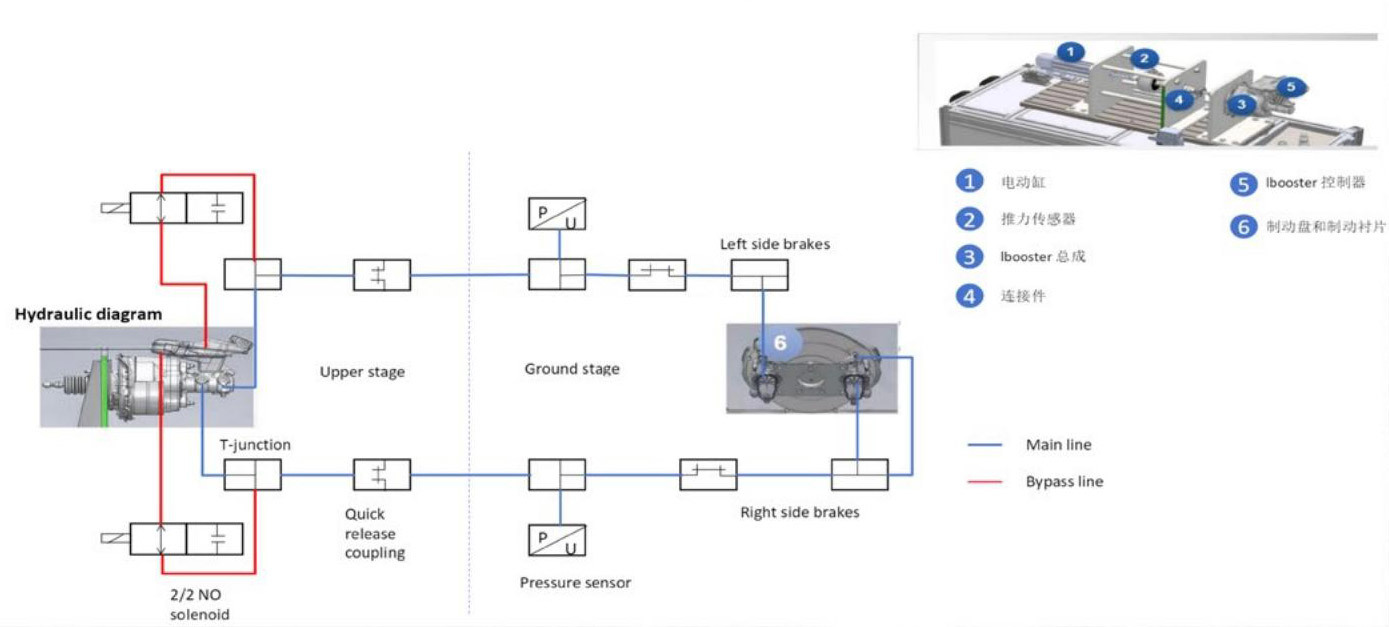

Typical Test Scenarios

Typical application of ibooster in the loop in the wet brake system solution: Ibooster uses a real hydraulic test bench. CarMaker outputs the brake pedal opening and converts it into a push rod stroke signal. The electric cylinder is position-controlled based on this signal to push the Ibooster push rod to move the corresponding displacement. The displacement sensor in the Ibooster assembly obtains the displacement information and transmits it to the controller. The controller calculates the required deceleration of the vehicle, controls the execution motor to assist, and converts it into master cylinder pressure together with the push rod force and transmits it to each wheel cylinder. The oil pressure sensor collects the wheel cylinder pressure and gives it to the vehicle model to realize braking, thus achieving closed-loop control of Ibooster.

Previous Page:

Next Page:

Contact Us

Room B402, No. 100, Lane 4088, Luoshan Road, Beicai Town, Pudong New Area, Shanghai

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.